External insulation

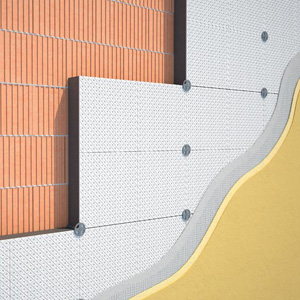

The thermal coat is an insulating layer made of various materials that is placed outside the building and completely covers the façades, like a "coat" covering the building.

During the design and installation phase, maximum care must be taken to ensure that no thermal bridges remain. That is, areas that allow an easier passage of heat.

The thermal coat can be made of various insulating materials including rock wool, glass wool, wood fiber, polystyrene and eps.

Nowadays specific materials are proposed for the realization, like for example pre-cut eps panels.

These panels are glued using specific cement-based glues to the building façade, then specific plastic plugs are applied to secure the panels on the vertices. At the end the panels are plastered drowning in the layer of plaster of the plastic nets that allows to contain the effects of shrinkage and dilatation preventing cracks.

The panels are supplied in different thicknesses from 40 mm to 100 mm and more. Clearly, the thickness will be greater and the insulation effect will be greater.

Economic advantage, because throwing money from the window

Given the increasing cost of energy, the thermal coat allows tangible savings on heating bills.

Incentives have been introduced for the construction of works that allow energy redevelopment of the building.