Electric welding

The electric weldings allow to quickly join profiles in unpainted ferrous metal. This type of structures can be used to create fixed furniture or the skeleton, for example, of a plasterboard bookcase.

Once the profiles have been cut to size, they must be degreased with alcohol or diluent, placed in position and pointed (stopped with small temporary welds).

At this point the final welding will be carried out along the contact surfaces.

The electric welds provide molten material and can be made with continuous wire machinery that releases the filler material collected in a reel automatically during welding.

Or with an electrode that is consumed with use and must be periodically replaced.

Aesthetic finish

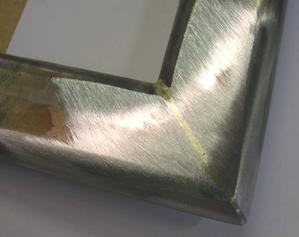

After joining two profiles that are not subject to particular loading, the weld can be milled with a flexible disk with sandpaper disc.

This will eliminate excess thickness.