The use of fired bricks is certainly a widespread practice, but to create biocompatible works, it will be necessary to put some attention on the technical characteristics of the bricks used:

Let's see some properties to keep in mind:

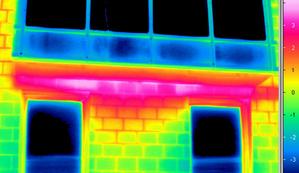

Thermal insulation

Frost resistance

Physical inability

Acoustic insulation

Resistance to fire

Other essential characteristics to define suitable for green building a brick are:

Brick microporization

The bricks that offer the best insulating performance are those subjected to microporization treatment.

This process creates discontinuities inside the brick which improve its insulation performance.

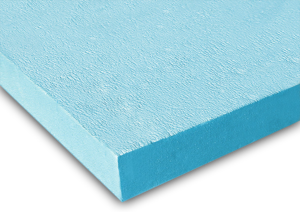

This process can be made with polystyrene, which however emits toxic gases during processing and residues inside the brick.

For this reason, microporization should preferably be done with wood sawdust or calcined rice chaff.

Polystyrene, also called erroneously polystyrene is produced from styrene, this substance has different toxic effects on humans.

This substance has been officially recognized as a carcinogen by the US Department of Health in the XII on carcinogens of 10 June 2011.

- 200-400 ppm (parts per million) dissolved in the air cause irritation to the mucous membranes, headache dizziness and drowsiness, memory disturbances and decreased reflexes.

- 500 ppm create continuous irritation and cough

- 800 ppm creates reduction of muscle strength and depression

- In a liquid form the contact creates dermatitis and cracks in the skin.