The Coprax pipe system allows you to create systems by hot-welding pipes, joints and sleeves very quickly. All parts of the system are made of a particular type of Polypropylene (Random Copolymer VESTOLEN P9421) designed specifically for this use.

In case you want to join these pipes with those with threaded joints it will be; You can do this by using the sealant, Teflon tape or hemp as you normally do.

The implementation phases are:

- Cut the pipe to size with the appropriate shear checking that the cut is clean and free of smudges

- Prepare the polyfuser by waiting for it to reach operating temperature

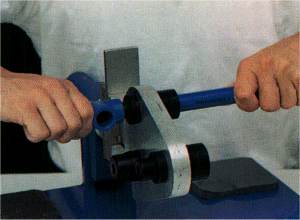

- Insert pipe and joint on the polyfusion unit so that they are brought to temperature (the heating time depends on the diameter of the pipe)

- Disconnect the hose and connection from the polyfusion unit and couple them together. Keep the position. At this stage it is possible to perform small joint orientation corrections.