How to choose water stones?

Japanese water stones, both natural and synthetic, are known for their rapid sharpening, not only for Japanese tools, but also for their Western counterparts.

The particles that produce the sharpening are bonded together in a soft way, so that during processing those found on the surface are quickly removed, leaving room for fresh and highly abrasive particles.

These water stones should only be lubricated with water! Never use oil!

The wide range of stones on the market will enable the expert to find, among many famous producers, the ideal stone for his needs. As each manufacturer studies their stones to achieve a different mix of characteristics, and those characteristics can vary greatly between different stones, for an optimal combination of sharpening stones most carpenters choose stones from different manufacturers.

If you get to know the characteristics of certain types of stones, it may be that a manufacturer is able to supply all the stones one needs, which in some cases can be an advantage. But there is not the right solution for all situations: the stones must adapt to the needs and way of working of each of us.

Conversely, such a large range can make it difficult to select the right combination; therefore we offer you a small guide to assist you at least in the initial choice.

First of all, the different manufacturers:

- Matsunaga, which produces the KING and SUN TIGER brands, is perhaps the best known manufacturer in Europe. Its strong point is the production of very traditional soft stones , which sharpen quickly and quickly expose fresh abrasive particles. This kind of stones need to be ground very often to keep them flat and effective.

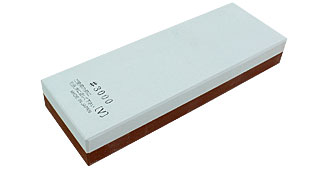

- Suehiro's CERAX and SUEHIRO stones are slightly harder, and therefore do not wear out as fast as traditional Japanese stones. With the 8000 stones you get perhaps the sharpest edge ever with a mirror finish on chisels and similar irons. Suehiro also offers a small combination stone for those who don't sharpen every day and who are reluctant to spend so much on a Cerax stone.

- SHAPTON stones are perhaps the hardest Japanese stones ever. They stay flat for a very long time and so if you are looking for a stone that is coarse enough to sharpen quickly and without having to grind them very often, these are probably the right choice. Fine-grained stones also work very well. But SHAPTON stones do not give the same surface and mirror as softer stones.

The greatest advantage of NANIWA stones is mainly related to their finer grains. No other stone can guarantee you such a perfect mirror finish.

A sharpening experience similar to that of natural stones is offered by the BESTER water stones of Imanishi, in Kyoto. BESTER water stones are of medium hardness, require a moderate amount of water and complete their task quickly.

With their best-of-breed Select II series, Tokyo-based manufacturer SIGMA Power Corporation caters to those using high-alloy steel tools such as HSS steel. These stones are also obviously geared towards producing a sharpening experience similar to that of natural stones. The special manufacturing process is expensive, but Sigma Select II stones probably have no equal when it comes to abrading steel.

JUUMA sharpening and polishing stones have a simplified principle of use and at the same time ensure the highest possible quality in the grits offered.

JUUMA Cobalt Blue stones consist of aluminum oxide and a binder. The addition of cobalt serves to slow down the abrasion of the stone and to increase the sharpening speed.

The increased speed is especially noticeable when sharpening blue steel ("blue paper" steel is often used for Japanese chisels and plane irons). Cobalt gives the stones their blue color. JUUMA sharpening stones are produced by a renowned Japanese sharpening stone manufacturer.

We endeavor to recommend Japanese natural water stones only to experienced users who are deeply familiar with synthetic Japanese water stones.

Not everyone likes natural stones and there are many uncertainties about their grain, which cannot be exactly determined.body, their hardness and their usability for certain types of steel is not suitable.

Which stone to use, according to your needs?

For a coarse sharpening that eliminates large marks or when the blade is particularly worn, stones from 120 to 400 are required. We recommend stones from 120 to 240 in this case.

For normal sharpening we recommend stones between 700 and 1200.

To remove the scratches and burrs left by the coarser stones, and to polish the surface, stones from 2000 upwards can be used. An upper limit theoretically does not exist, but at the same time stones over 10000 do not produce appreciable improvements in the wire.

Also note that beyond 8,000 there are no Japanese standards of measurement. Given how many stones claim to have an extremely fine grain, one can only trust the producers.

For those with some experience in sharpening, we recommend an 8000 grit finishing stone. If in doubt, or for beginners, stones with a grit between 3000 and 6000 will produce acceptable results.

So, in conclusion, it takes at least three stones to do a good sharpening job: one to grind, one to sharpen and one to polish.

For those who only sharpen occasionally and don't plan on having to remove major damage, a combination stone might be fine. The measure chosen will derive from a trade off between cost and speed. The larger the stone, the faster the work will proceed. Even with small stones you will do a good job, but it will take a little longer.