The spinning

Spinning is a very effective bonding technique applicable to many materials from solid wood to particleboard. It is made by drilling the two pieces to be joined with corresponding holes and inserting into them the pins which, through the gluing, make the joint solid.

To facilitate the drilling, there are particular clamps called spigot that facilitate the operation or you can make the holes on one piece and insert the trace-witness plugs that with their pointed head mark the exact position in which to drill holes on the piece to be joined.

The spinning is then said passing through if it completely crosses at least one of the parts to be joined, this type of spinning can realize a decorative element of the piece of furniture.

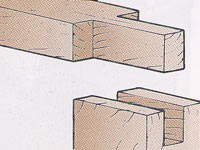

Tenone and Mortasa

This technique makes very strong joints and consists in the realization of the T-shaped element called Tenon and its respective joint called mortise.

They are then joined with glue or a wooden wedge passing through the protruding part of the tenon if passing.

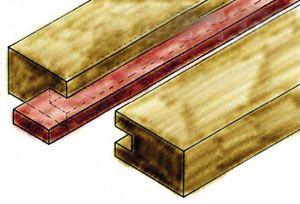

Tab reported

In this case the faces of the panels to be joined are milled correspondingly.

Next you insert a tab that is glued to complete the joint.

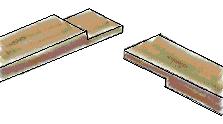

Interlocking with wood

The half-timber interlocking is achieved by thinning the two parts to be joined so that once they are brought together they are invisible.

The ideal is that the thinned section is the destination of the total available interlocking.

Union to "L"

It is a type of two-part union through a third that is glued and shaped to make the joint ideal and stable.

You can use it to make L junctions without any elements being visible on the outside.

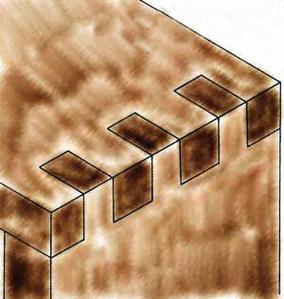

Interlocking and serrated

The two parts that create the joint are serrated so that they fit perfectly, creating a very strong corner joint.

It is one of the most difficult joints to make because the wood on the head is difficult and makes it prone to chipping, but the aesthetic result is particular and pleasant if the work is well done.

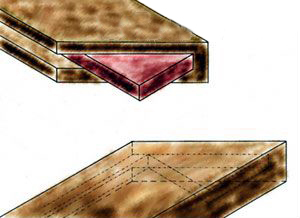

Dovetail union

This joint is similar to the serrated one, but in this case the teeth are made with a triangular shape called dovetail that makes the joint even more solid.

There are special templates to be superimposed on the piece on which to make the indentation to facilitate the operation.